NEWS

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333

NEWS

The process of incorporating different liquids into a batch mixer is a critical step in various industrial applications.

This article will explore the challenges associated with achieving homogeneity when mixing immiscible liquids, such as oil and water in a solid mash.

Understanding the chemical properties of the liquids used, as well as employing appropriate mixing techniques, is essential to prevent issues like stratification, poor homogeneity, lump formation, and increased energy consumption.

Batch mixers are widely used in industries such as food processing, pharmaceuticals, animal feed, Pet food, chemical and materials manufacturing to blend solids and liquids into a homogeneous mixture. However, achieving uniform distribution of liquids within the solids can be challenging, especially when dealing with immiscible liquids like oil and water. The homogeneity of the final product, often measured by the Coefficient of Variation (CV), is influenced not only by the type of mixer but also by the properties of the liquids involved.

Discover the importance of premixing immiscible liquids using dedicated homogenization equipment to enhance the final product quality and operational efficiency.

The ability of liquids to mix and form a single homogeneous phase is governed by their chemical properties. Liquids that can combine and form a new, uniform liquid are termed “miscible”. Conversely, liquids that resist mixing and instead form separate layers are referred to as “immiscible”. A classic example of immiscible liquids is oil and water, which naturally separate due to differences in polarity and density.

MISCIBLE LIQUIDS

IMMISCIBLE LIQUIDS

When immiscible liquids like oil and water are added separately to a batch mixer, several problems can arise:

DOSING AND HOMOGENISING

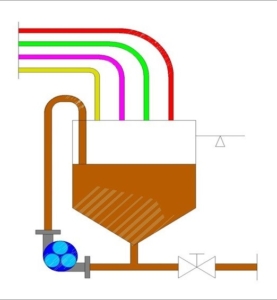

Achieving homogeneity in a batch mixer when working with immiscible liquids is a complex challenge that requires careful consideration of the liquids’ properties and the mixing techniques employed. That’s why PLP Systems has created The EML series homogenizer machine, used in all areas where there is a need to mix and emulsify various liquids or powder dispersions. Placed below the threshold of a tank, thanks to the pumping effect, allows the circulation of liquids in the container.

The intense cutting effect resulting from the combination of mechanical and hydraulic processing of the “rotor” and “stator”, a powerful “shear” effect is generated on the product. This process ensures a highly mixed consistency and perfect homogeneity, ensuring high-quality results for the finished product.

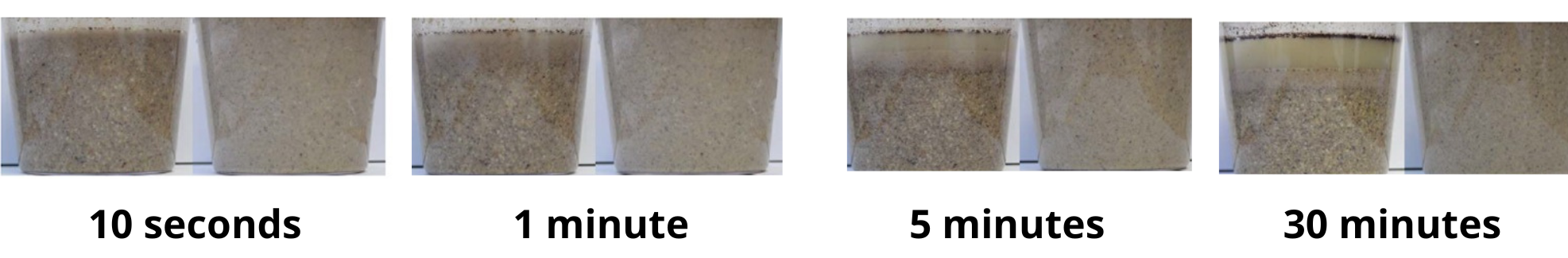

Comparision of liquid feed separation times. The sample on the left was obtained using a traditional mixer, while the one on the right was obtained using our EML Homogenizer.

Fig. 1-2, 70% vegetable oil; 30% H₂O. Fig. 3-4, 40% molasses, 40% vegetable oil, 20% H₂O. Comparision of liquid feed separation times. The sample on the left was obtained using a traditional mixer, while the one on the right was obtained using our EML Homogenizer.

By premixing immiscible liquids using a EML homogenizer, manufacturers can overcome many of the issues associated with direct mixing, leading to improved product quality. As industries continue to demand higher standards of quality and efficiency, the adoption of advanced mixing and homogenization techniques will become increasingly important for different industries.

EML SERIES – PLP HOMOGENIZER

PLP Systems specializes in both liquids and powders, with a special focus on the pet food and feed industries. An important area for PLP is the accurate management of liquids and powder for feed production, with a specific focus on post-pellet coating. This process involves adding micro-liquids such as enzymes, vitamins, flavors, probiotics amd yeast to the pellets, aiming to enhance their quality.

Whether you’re looking to improve your current production line or explore innovative methods to increase product appeal, our technologies offer the reliability and excellence you need.

Need more information or want to dive deeper into our liquids dosing and mixing systems?

We’re here to provide tailored solutions and answer all your questions.

Call us today at +39 0523 891 629 or email us at info@plp-systems.com for a free consultation.

We’re here to help you find the perfect solution for your needs!

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333

WELCOME TO NEIL FINNEY – NEW REPRESENTATIVE FOR PLP SYSTEMS IN UK

WELCOME TO NEIL FINNEY – NEW REPRESENTATIVE FOR PLP SYSTEMS IN UK