NEWS

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333

NEWS

PLP Systems has engineered a range of motorized and static sprayers designed to achieve uniform distribution and injection of both liquid solutions and dry powders, effectively mitigating the risk of nozzle blockage. These technologies are particularly valuable in applications involving high-viscosity liquids, such as liquid digest or hydrolyzed proteins used as potent palatants in pet food.

In a wide range of industrial sectors, from animal feed to pet food processing, the efficient combination of liquids and solids is essential. Whether injecting liquid formulations into batch mixers or coating products with additives or flavour enhancers, the key lies in effectively dispersing the liquid over a broad surface area.

This process plays a particularly important role in pet food and animal feed production, where liquids such as palatants, vitamins or nutritional additives are applied to enhance product quality and appeal.

There are three primary methods used to achieve this liquid-solid integration: spraying, atomizing, and nebulizing. Each technique is based on distinct technologies designed to accommodate different types of liquids and application needs.

Among these, advanced solutions such as PLP Systems’ SMOG atomization technology stands out, offering highly efficient dispersion that improves palatability and consistency in the final product.

Is the most common method and widely used across various applications. It is suitable for liquids of different viscosities, producing relatively larger droplets, typically in the range of hundreds of micrometers in diameter. These droplets are generally more visible and can cover surfaces more thoroughly, delivering a larger amount of liquid.

Spraying is often employed when a medium or large amount of liquid needs to be added to a batch mixer. The larger droplets tend to fall quickly due to gravity, making spraying ideal for applications where homogenous absorption of the liquid by the solid is desired.

Spraying is mechanically generated by reducing the exit section, or “nozzle,” and increasing the pressure in the pipeline.

The shape of the nozzle allows for different spray patterns, including:

Involves breaking the liquid into very fine droplets. While it is possible to use viscous liquids, not all atomizing technologies can handle higher viscosities. The droplet size typically ranges from 10 to 300 micrometers in diameter.

This method is used when a medium or small amount of liquid is added to a batch mixer, enhancing the homogeneity and dispersion of the product within the solid. Atomizing is also common in coating processes where even coverage of a solid surface is critical, such as in painting, food flavouring and pet food greasing.

Different technologies are used for atomization, depending on the application and liquid properties:

Motorized SMOG atomization: This method, used by PLP Systems, combines rotary and air-Assisted atomization. The liquid passes through a spinning closed chamber; when the small droplets exit the nozzle, air jets further reduce the particle size. This technique is particularly useful for viscous liquids such as oils, fats, creams, hydrolysed pastes, molasses, syrups, chocolate, honey and more.

Motorized SMOG atomization: This method, used by PLP Systems, combines rotary and air-Assisted atomization. The liquid passes through a spinning closed chamber; when the small droplets exit the nozzle, air jets further reduce the particle size. This technique is particularly useful for viscous liquids such as oils, fats, creams, hydrolysed pastes, molasses, syrups, chocolate, honey and more.Nebulizing produces much finer droplets, often only a few micrometers in diameter. These droplets are so small that they can remain suspended in the air as a mist or aerosol. Due to this characteristic, nebulizing is not typically used for adding liquids in mixers or coating applications. Instead, it is commonly employed for dispersing aerosols into the air for disinfection purposes.

In pet food production, palatants are typically applied post-oil coating to enhance the external flavor profile of kibbles. Achieving optimal palatability hinges on the even distribution of these viscous substances across all kibble surfaces. Traditional spraying methods often struggle with high-viscosity liquids, resulting in inconsistent coverage and potential nozzle clogging.

To overcome these challenges, PLP Systems developed the SMOG technology. This advanced atomization system excels in spraying high-viscosity liquids onto kibble surfaces or within batch mixers, ensuring precise and uniform application.

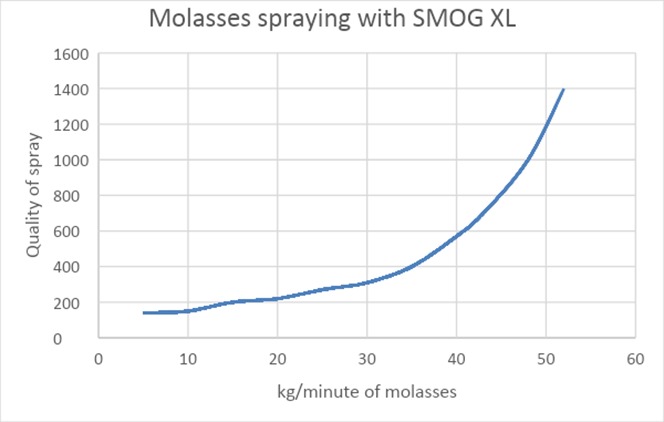

The SMOG XL series of sprayers is specifically engineered to handle molasses, a highly viscous liquid, across a broad range of viscosities. Achieving optimal spray quality with molasses necessitates careful control of the flow rate. As viscosity increases, the flow rate must be reduced to maintain a consistent and fine spray pattern.

The higher is the viscosity of the molasses the less should be the flow rate in order to obtain a good quality of spray.

Below an example of the curve trend of molasses spraying at different flow rates. This however depends on the viscosity, the temperature of molasse, the quantity of air of the blower, the type of pump used and the application.

PLP Systems specializes in both liquids and powders, with a special focus on the pet food and feed industries. An important area for PLP is the accurate and precise handling of liquids and powder for pet food and feed production, with a specific focus on post-pellet coating and kibble palatability enhancing.

This process involves adding micro-liquids such as enzymes, vitamins, flavors, probiotics amd yeast to the pellets, aiming to enhance their quality and oils, digest and palatants to kibbles.

Whether you’re looking to improve your current production line or explore innovative methods to increase product appeal, our technologies offer the reliability and excellence you need.

Need more information or want to dive deeper into our systems?

We’re here to provide tailored solutions and answer all your questions.

Call us today at +39 0523 891 629 or email us at info@plp-systems.com for a free consultation.

We’re here to help you find the perfect solution for your needs!

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333