NEWS

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333

NEWS

PLP Systems has successfully completed the supply of the MLBS-500 (Multi Liquid Batch System) for a feed production facility. The system was fully engineered to meet the specific production needs of the customer, with a strong focus on dosing precision, liquid homogenization, and operational reliability in dust-classified environments.

All components installed are compliant with ATEX Zone 22 regulations, ensuring the highest standards of process safety.

At the heart of the system is a 500-liter stainless steel tank equipped with load cells for level management. It features a high-efficiency vertical mixer and a homogenizer designed to ensure consistent and complete emulsion of liquids before they enter the mixing phase. Product movement is managed by a stainless steel volumetric pump, supported by a fully integrated recirculation and cleaning loop with bypass capability.

The installation also includes a dedicated water dosing module, consisting of a storage tank, centrifugal pump, filtration unit, level sensors, and flow measurement instrumentation. For emulsifiers and colorants, the system provides a complete solution with IBC support frames, gear dosing pumps, continuous level sensors and three-way control valves, designed for accurate and automated flow handling.

The installation phase included the placement of the MLBS system near the main mixer, full integration with existing plant lines, and the supply and installation of all stainless steel connection piping between tanks, dosing modules, and the central system.

The entire configuration enables smooth integration with the existing production line, minimizing cycle times, reducing waste, and ensuring repeatable dosing across batches.

This supply represents a comprehensive solution for feed manufacturers seeking efficient, automated, and regulation-compliant liquid dosing systems. Commissioning is scheduled in the coming weeks, marking the final stage of a project that combines process engineering, automation and consistent product quality.

PLP Systems specializes in both liquids and powders, with a special focus on the pet food and feed industries. An important area for PLP is the accurate management of liquids and powder for feed production, with a specific focus on post-pellet coating. This process involves adding micro-liquids such as enzymes, vitamins, flavors, probiotics amd yeast to the pellets, aiming to enhance their quality.

Whether you’re looking to improve your current production line or explore innovative methods to increase product appeal, our technologies offer the reliability and excellence you need.

Need more information or want to dive deeper into our liquids dosing and mixing systems?

We’re here to provide tailored solutions and answer all your questions.

Call us today at +39 0523 891 629 or email us at info@plp-systems.com for a free consultation.

We’re here to help you find the perfect solution for your needs!

PLP Systems SRL

Strada Provinciale 21, N° 303

29018 Lugagnano Val d’Arda

Piacenza, Italy

P.IVA 01373620333

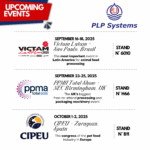

UPCOMING EVENTS, COME JOIN US – PLP Systems

UPCOMING EVENTS, COME JOIN US – PLP Systems